THE OBERURSEL RESTORATION

- Evan James

- Mar 1, 2020

- 2 min read

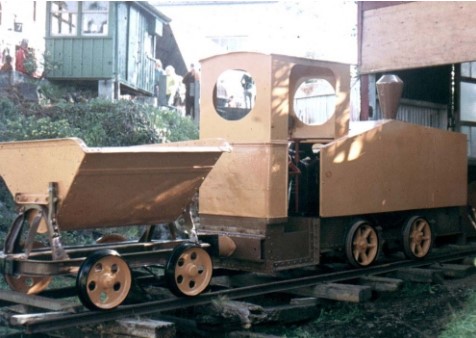

New Zealand's oldest internal combustion powered locomotive, made in what is now claimed to be the world's oldest surviving aircraft engine factory, is a current restoration project of the Rail Section's locomotive team.

It is the Oberursel locomotive, produced in 1912 by Motorenfabrik Oberursel, a German manufacturer of locomotive, automotive and aircraft engines, which had its factory near Frankfurt.

Oberursel was famous for WW1 Gnome rotary engines which were used in fighter planes such as the Fokker Eindecker and E1. Today the same factory, as part of Rolls-Royce Deutschland, is producing the engines used in passenger airliners.

The Oberursel locomotive was originally 2 foot gauge and was purchased by the Thames Valley Drainage Board to work on drainage schemes on the Hauraki Plains.

In 1940, after conversion to 3ft6in gauge, the locomotive and its accompanying wagons were sold to NZ Mercury Mines, which used them at its Puhipuhi mine located between Whangarei and Russell. The mine was closed in 1945 and the locomotive lay derelict until being donated to MOTAT in 1968, along with two side-tipping wagons. The locomotive was partly restored some years ago and was used mainly as a stationary exhibit.

Since then the motor has been restored by MOTAT and has been displayed in the vintage internal combustion display alongside vintage tractors, and a start had been made on dismantling the rest of the locomotive, but work stopped because of other more pressing commitments.

The current restoration began in 2019 and is being run in tandem with MOTAT's other small vintage German loco, Bertha. Rail Section's Martyn Radford reports that work was started on the Oberusel as there wasn't enough work to keep everyone busy with Bertha's boiler rebuild. Current work has concentrated on the chassis, with all work so far being done in-house.

First up was making a new axle box keeper to replace a missing one. Then remaining bits of the axles were removed from the wheels which entailed gas cutting the retainer bits as flush to the wheels as possible, then boring a hole through what was left of the axle. After that a slot was gas cut from the hole to the edge of the wheel and the remaining piece of axle was simply knocked off.

Next it was the turn of the axle boxes which, after the white metal bearings had been removed, were found to be in a very poor state. Martyn has said that the decision was made to build up the axle box housing with weld and to machine them all true again before making new bronze bearings. The thrust faces were then tidied up and the opposite sides machined true.

Although the locomotive is not likely to get used in regular service Martyn believes it would be a valuable starting point for MOTAT's extensive collection of internal combustion engine locomotives.

The MOTAT internal combustion rail locomotives include a Planet construction loco from 1926, Hudswell Clarke shunter from 1936, Drewry Tr.21 shunter from 1939, EB.25 battery electric shunter from 1925 (converted to diesel electric in 1953), Dsa.223 diesel shunter from 1953, Tr.730 diesel shunter from 1960, and Da.1400 diesel electric mainline locomotive from 1955. - by Evan James

Historical information from “MOTAT Locomotives” a book published by Richard Croker, Philip Wrigley and Sean Miller, and from Wikipedia.

Comentarios